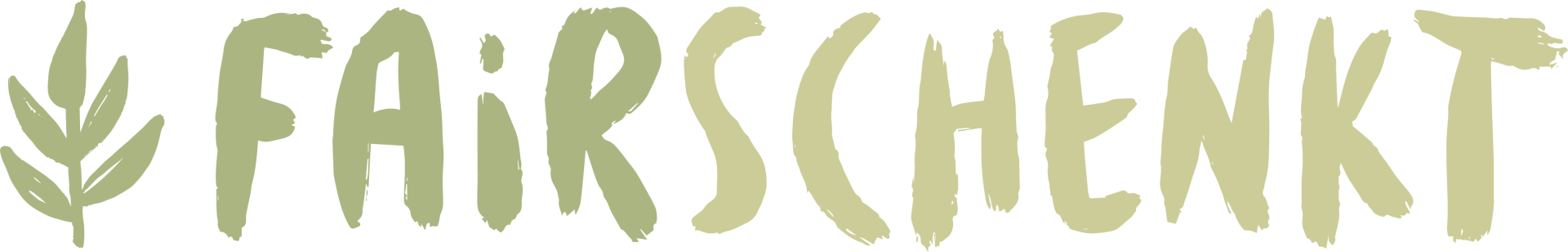

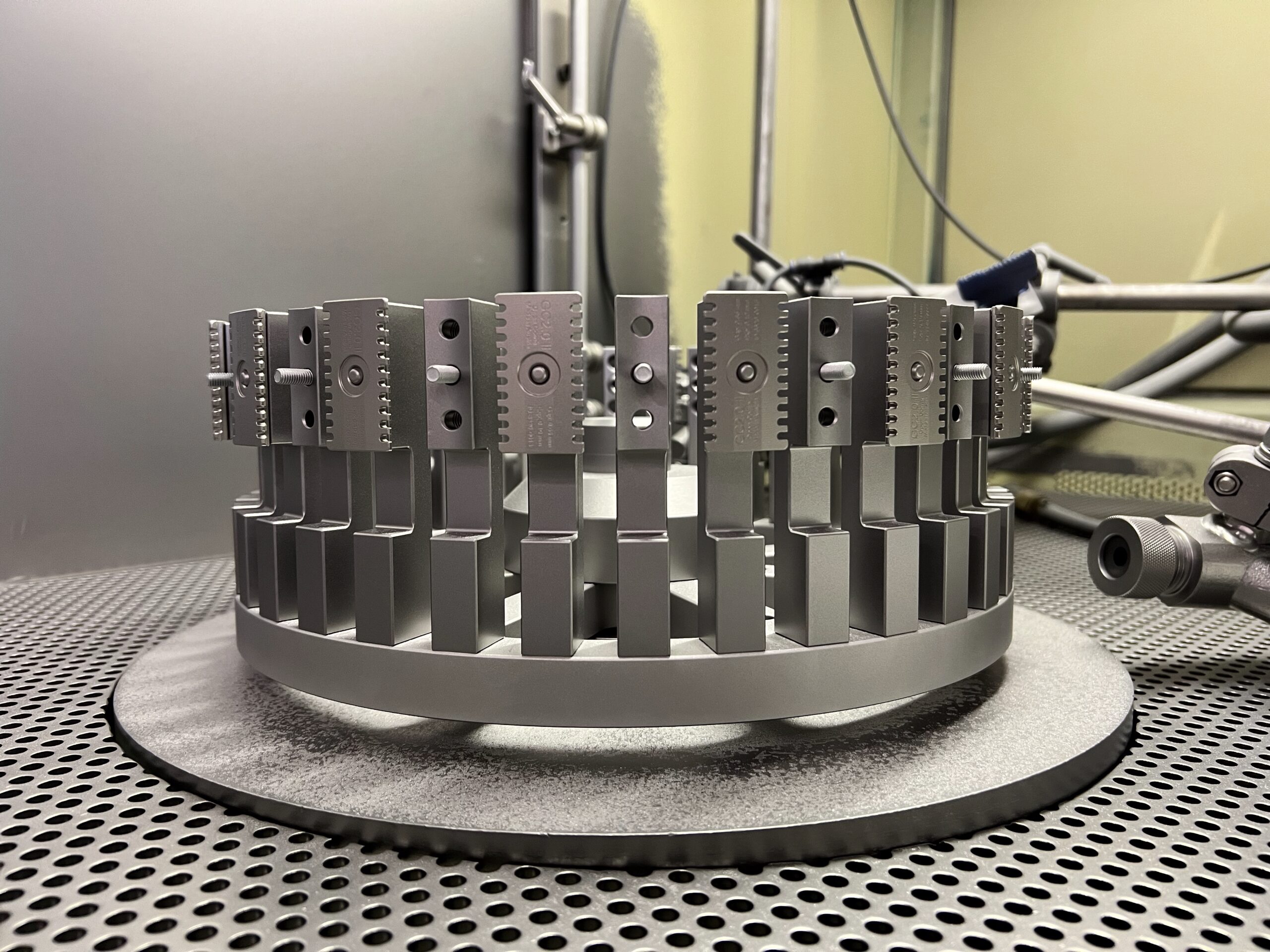

Our Double Edge Razor GC2.0 - CNC-milled precision from Austria

Our Greencult razor GC2.0 is the premium successor of our Allrounder-Razor GC1.1. Shorter handle, new design, different base plates and sand blasted finish. The razor is made of 303 stainless steel in Austria.

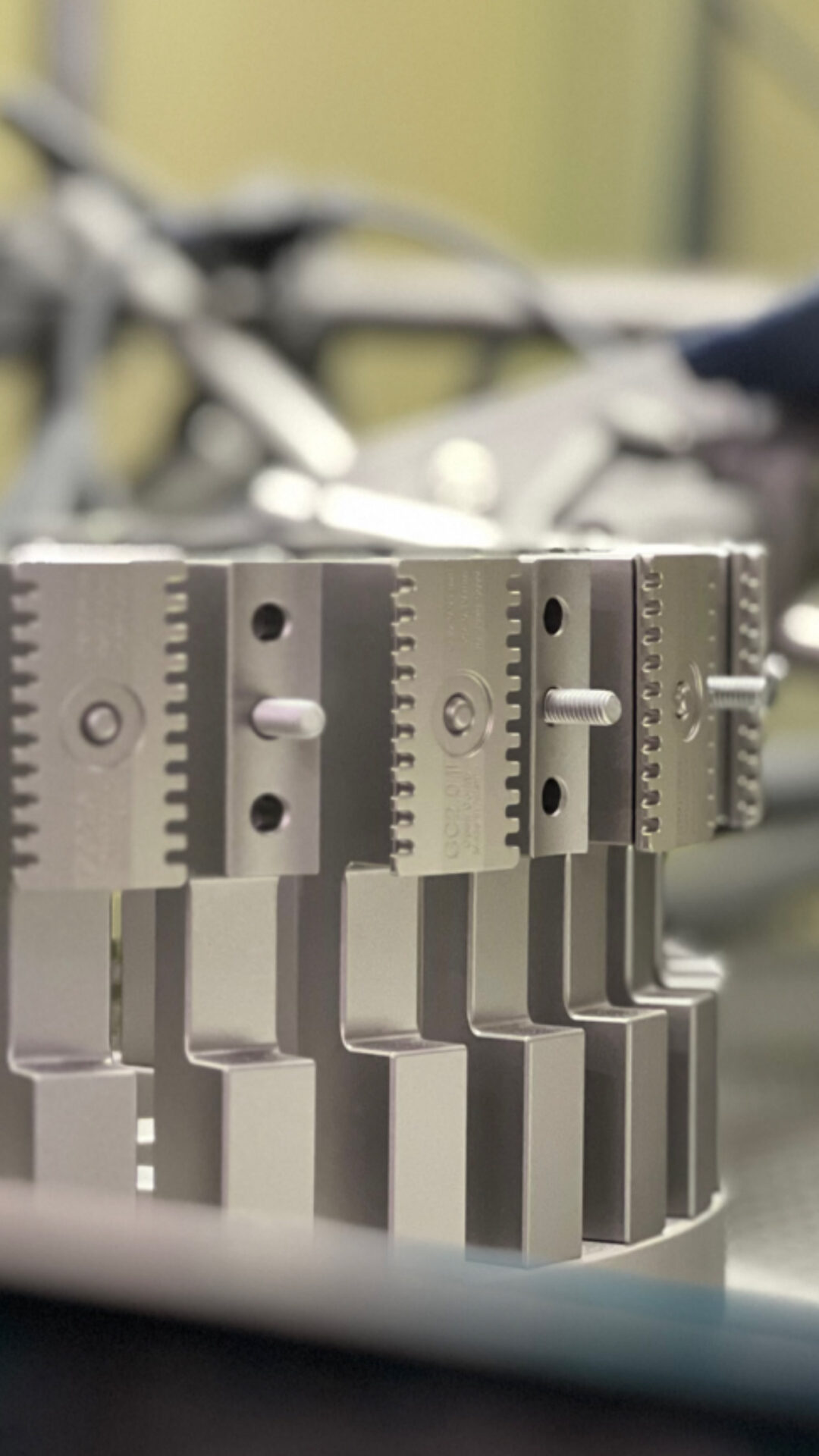

Unlike commercially available razors, most of which come from Asia, ours is milled using the CNC process and made from one piece of steel. Production from high-quality stainless steel offers some advantages such as individual tolerances, a better blade fit and a more robust material.

What makes our GC2.0 special:

![]() 100% Made in Austria: in our family business in Goetzis, Vorarlberg

100% Made in Austria: in our family business in Goetzis, Vorarlberg

![]() functional design: shorter handle, new design, different base plates and sand blasted finish

functional design: shorter handle, new design, different base plates and sand blasted finish

![]() hidden blade ends: A razor head where the razor blade does not protrude from the side – no more unnecessary cutting!

hidden blade ends: A razor head where the razor blade does not protrude from the side – no more unnecessary cutting!

![]() made from stainless steel: the entire razor is made of 303 stainless steel, which is 100% sourced from Europe (AT,DE, IT, PRT, etc. depending on the supplier). We do not have a chrome-plated surface (chemical environmentally harmful production process due to inferior base material) like many of the other razors on the market.

made from stainless steel: the entire razor is made of 303 stainless steel, which is 100% sourced from Europe (AT,DE, IT, PRT, etc. depending on the supplier). We do not have a chrome-plated surface (chemical environmentally harmful production process due to inferior base material) like many of the other razors on the market.

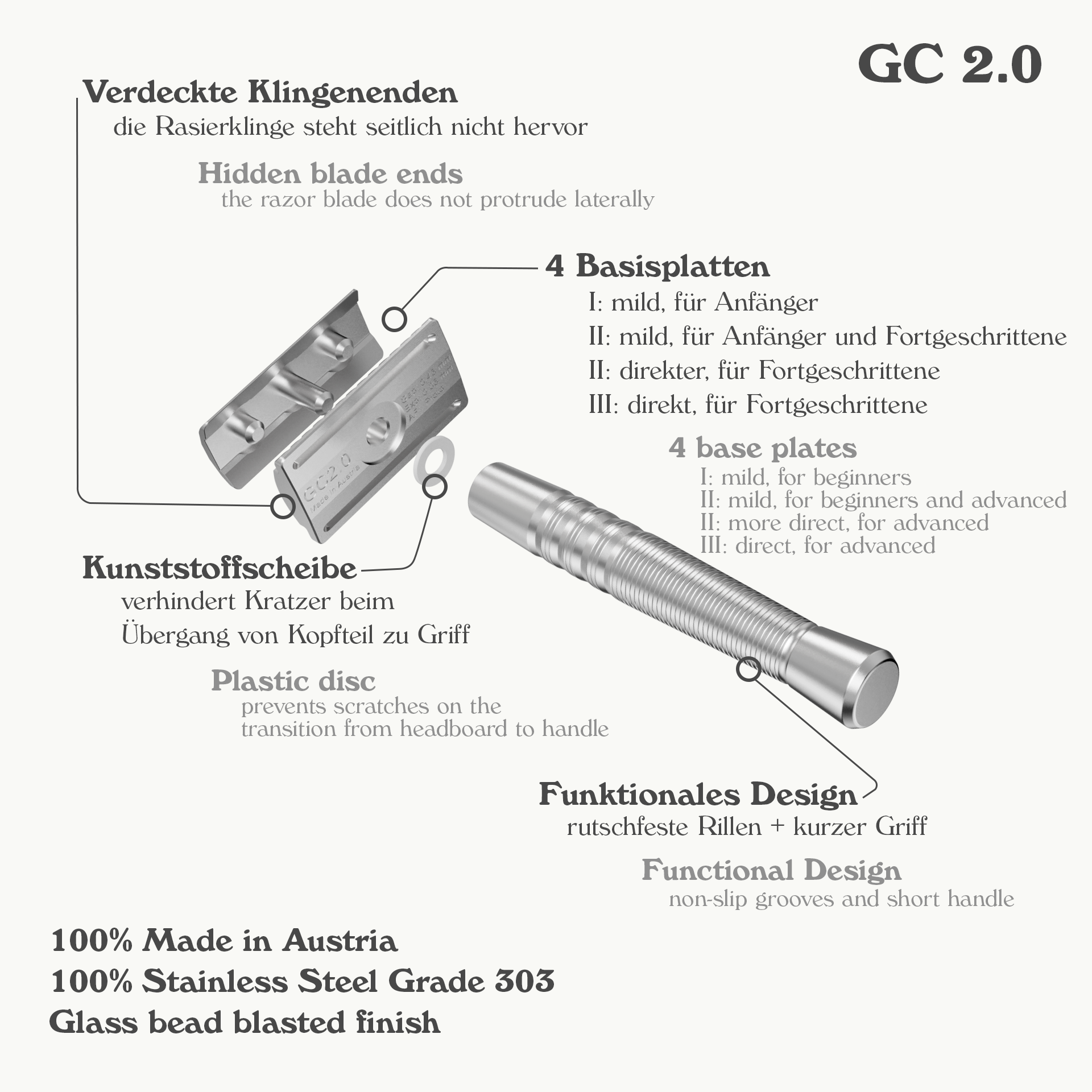

![]() 4 base plates:

4 base plates:

- I: suitable for beginners, for daily shaving.

“With the I plate, it is just as you would imagine a gentle razor to be. 100% safe, 100% non-irritating, yet thorough.” – customer feedback

- II: suitable for beginners and advanced shavers, for daily shaving, slightly more lasting than I

“A simple and straightforward shave. More thorough than with plate I. Slightly less bladefeel than the III but little difference in result.” – customer feedback

- III: more direct, advanced, for a 3-day-old beard.

“The III plate is noticeably milder than IV, but still direct. To match plate IV, it would need a much sharper blade.” – customer feedback

- IV: direct, advanced, for a 3-5 day beard.

“The IV plate is thorough, direct, very sustainable, and brilliant for someone with a 5 day beard and experience, but not for beginners.” – customer feedback

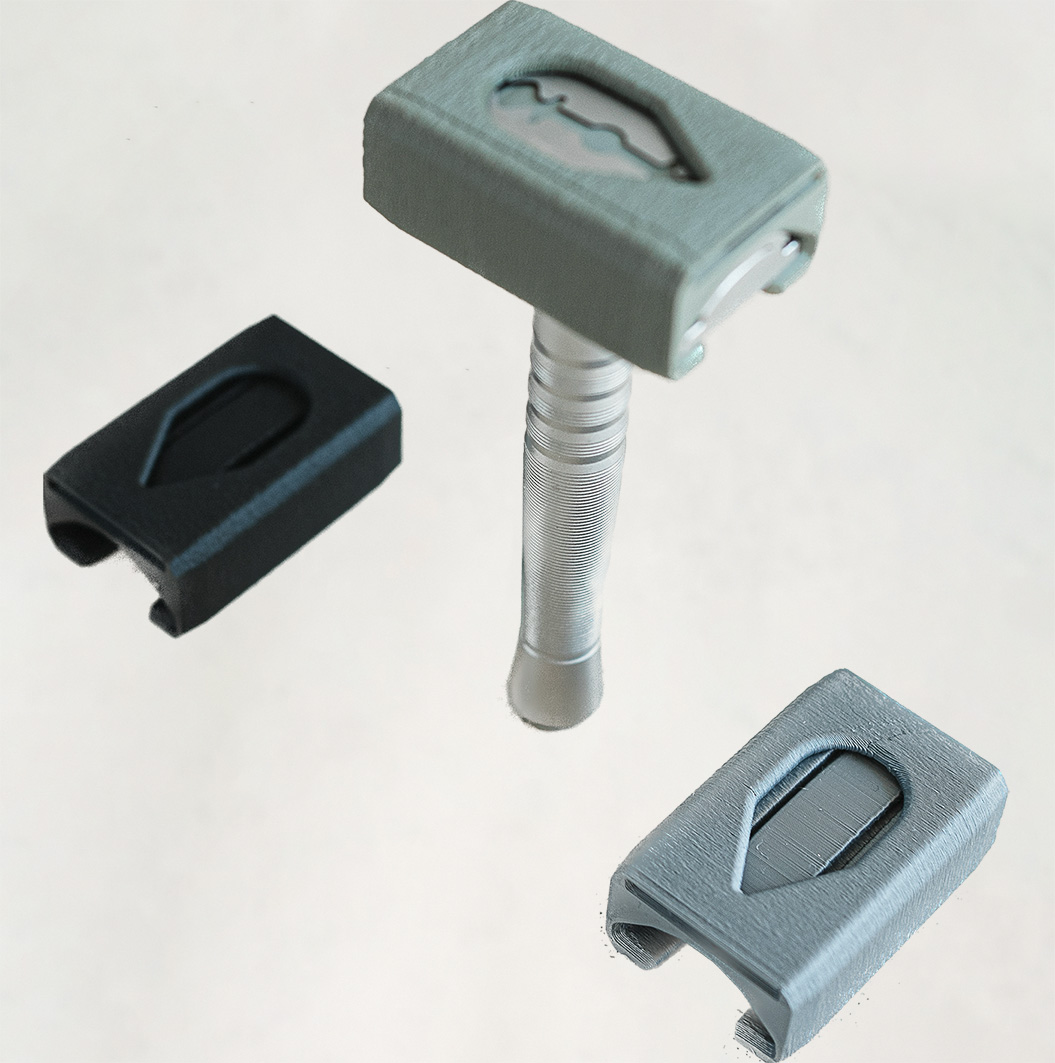

![]() Plastic disc as scratch protection: as a special highlight, we have pressed a plastic disc directly in the handle. This prevents scratches from occurring between the two metal parts at the transition to the headpiece. If you don’t want this, you can simply remove the disc. The M5 thread in theory only needs 2.5-3 turns of the thread to reach the full tensile strength of about 300kg – so there is no restriction in this regard.

Plastic disc as scratch protection: as a special highlight, we have pressed a plastic disc directly in the handle. This prevents scratches from occurring between the two metal parts at the transition to the headpiece. If you don’t want this, you can simply remove the disc. The M5 thread in theory only needs 2.5-3 turns of the thread to reach the full tensile strength of about 300kg – so there is no restriction in this regard.

![]() Glass bead blasted finish: this brings out a velvety uniform surface. Our finish cannot be described as “matt” as it has a brilliant sheen. Furthermore, the abrasive compacts the surface and brings a pleasant feel. The grain size of the abrasive is in the 0.001 mm range.

Glass bead blasted finish: this brings out a velvety uniform surface. Our finish cannot be described as “matt” as it has a brilliant sheen. Furthermore, the abrasive compacts the surface and brings a pleasant feel. The grain size of the abrasive is in the 0.001 mm range.

Coming soon

![]() Holder for razor: to be announced

Holder for razor: to be announced

![]() Blades + thread protector for travel: now released

Blades + thread protector for travel: now released

Further informations

Our GC2.0 is ideal for wet shaving with its short handle and 4 different base plates of either CC (closed comb) or OC (open comb).

Base plate I: Gap: 0.45mm, Exposure: 0.05mm

Base plate II: Gap: 0.65mm, Exposure: 0.10mm

Base plate III: Gap: 0.85mm, Exposure: 0.15mm

Base plate IV: Gap: 1.05mm, Exposure: 0.20mm

Nov 2019: Our Greencult razor goes live for the first time: with the handle of the current GC1, but with a purchased zinc cast head, as funds are still low.

Okt 2020: Go-live of the first Greencult razor 100% Made in Austria. The GC1.0. Now, in addition to the handle, the head is also regionally produced and 100% stainless steel with a gap of 0.95mm and a blade exposure of 0.25mm. This first model GC1.0 is currently no longer available.

July 2022: After our razor GC1.0 became known, demand and feedback increases. For this we revise our unisex GC1.0 model a final time according to the feedback of our customers. With a gap of 0.65 mm and an exposure of 0.10 mm, we have brought a high-quality and, above all, affordable unisex entry-level model onto the market: the GC1.1.

October 2022: Our premium razor GC2.0 is launched. 4 base plates, shorter handle and glass bead blasted finish. Of course made of 303 stainless steel and Made in Austria.

- CNC machined razor: we can achieve 0.01mm precision. This is NOT possible with stainless steel razors, which are cast or printed.

- Our GC2.0 is ideal for wet shaving with its short handle and 4 different base plates.

- As a special highlight, we have pressed a plastic disc directly into the handle by hand. This prevents scratches from occurring between the two metal parts at the transition to the headpiece. If you don’t want this, you can simply remove the disc. The M5 thread in theory only needs 2.5-3 turns of the thread to reach the full tensile strength of about 300kg – so there is no restriction in this regard.

- Glass bead blasting was used for the finish, as this brings out a velvety uniform surface. The finish cannot be described as “matt”, as it has a brilliant sheen. Furthermore, the abrasive compacts the surface and brings a pleasant feel. The grain size of the abrasive is in the 0.001 mm range.

Material: Stainless steel 303/1.4305 from Europe (mainly AT, IT and GER)

Care: you have your razor for eternity. Please do NOT store the razor blade in the razor if possible to avoid rust marks from the blades (you can of course remove them – it comes from the blade, not the razor).

Dimensions:

Handle length: 88 mm

Outer diameter maximum: 13,90 mm

Weight:

Handle: 80 g

Base plate: 32 g

Head part: 14 g

Customer reviews

Only logged in customers who have purchased this product may leave a review.

Transparency

Sustainability – where does it begin, where does it end?

For us, one thing is certain: the more you know as a consumer, the more conscious your decisions will be. Transparency is the first step toward genuine, sustainable consumption.

Origin

Traceability

100%

Production

Our family business

With the globalization boom of recent decades, many companies have shifted their production to Asia, relying on pure chrome plating over zinc casting.

Partnering with my husband who owns a second-generation metal processing company in the Rhine Valley, I set out to bring a high-quality Austrian-made model to the market—ensuring complete transparency in the process.

This journey led to our first model in late 2019, initially featuring a purchased head from Asia. Since 2020, we have been producing our GC1 razor (formerly GC1.0, now GC1.1) entirely in our family-run facility in Vorarlberg, Austria. This allows us to offer outstanding quality at an unbeatable price, with worldwide distribution.

Expanding our lineup, we now introduce the GC2.0—a unisex razor featuring a shorter handle and four interchangeable base plates, allowing for a customizable shave experience, from gentle to an ultra-close BBS finish.